The spraying of industrial wet paint generates small particle size spray mist in the surrounding air. This mist contains particles and volatile solvents from the paint mixture and those shall not be released onto the skin or into the breathing air. The use of industrial coatings is safe when personal protection is used to prevent the exposure. Protection must be in use during the all phases of the surface treatment process.

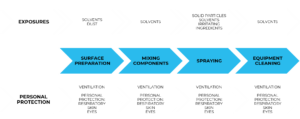

In the following picture, the surface treatment process is divided into four different stages, in all of which the worker may be exposed to different exposures. Protection must be remembered in all phases: surface preparation, mixing components, spraying and equipment cleaning.

You should ALWAYS protect yourself at every stage of the surface treatment process, detailed instructions on product-specific protection can be found in the safety data sheets (Section 8: Exposure controls/personal protection).

The right kind of personal protection for spraying: Protective work clothing and protective gloves, antistatic work shoes, a full mask to protect the eyes and face, and for respiratory protection motored air protector with proper filters.

RESPIRATORY PROTECTION:

If ventilation is insufficient, a half or full mask equipped with a suitable filter must be used.

Surface preparation: half- or full mask with gas filter A (organic substances), and when grinding P-type dust filter

Mixing components: half- or full mask with gas filter A (organic substances)

Spraying: Mask with combined filter (gas & dust) AP / ABP (depending on the product). In the continuous long-term work it is recommended to use motored air protector or separative protector (fresh air hood or compressed air hood or such).

Equipment cleaning: half- or full mask with gas filter A (organic substances)

The painter is equipped with a motorized full mask respirator, which also protects the eyes and face. The necessary filters can be found in the motor.

BODY PROTECTION:

Protective work clothing covering the skin and protective gloves in all work phases. Selection of the glove material on consideration of the penetration times, rates of diffusion and the degradation (gloves tested in accordance with EN374). The risk of hand dermatitis is highest among painters who use epoxy and polyurethane coatings on a daily basis. These coatings are both irritating and can cause allergies.

EYE/FACE PROTECTION:

Tightly sealed goggles in all work phases. The eye flushing device should be located near the the paint work area.

The eyes can be protected with goggles instead of a full mask. It is good to wear a full mask while spraying to ensure that paint particles do not get into the eyes and facial skin.

More detailed information on the safe use of industrial coatings: