Kuopion Rakenneasennus Oy has been painting its steel products with Nor-Maali´s industrial coatings since 2011. Over the years the company has expanded and production facilities have been upgraded accordingly. “In January 2023 a brand new surface treatment facility was opened that allows to paint larger pieces faster and more energy-efficiently”, says Teemu Tilles, CEO of Kuopion Rakenneasennus Oy.

Kuopion Rakenneasennus Oy

Established in 1987, Kuopion Rakenneasennus Oy is specializing in manufacturing and installation of mid- to heavy range steel structures. The product portfolio includes a variety of constructions types, such as, frame structures, bridge frames, platforms, stairs, chimneys, and tanks. Alongside these, the company provides a range of services such as blast cleaning, wet painting, and on-site welding, maintenance, demolition, and lifting tasks. “Our customer base is wide, we service comprehensively with our solutions. Our flexible production model supports both small and large-scale deliveries both for domestic and export”, CEO Teemu Tilles tells.

Kuopion Rakenneasennus is a family business, headed by CEO Teemu Tilles, and it is situated in Toivala, approximately 10 km from Kuopio. Over the years, Kuopion Rakenneasennus Oy has grown from a modest team of three metal workers to a contract based sub-contractor employing over 40 metal professionals. In response to increasing demand, the company moved to larger premises in the Neulamäki industrial area in 1997 and made significant investments in new machinery to enhance their production capabilities.

The expansion of the market in the 2000s led to the company establishing new premises in the Toivala business area in 2005. The current premises, purchased in 2014, reflect the company’s steady growth and development, underscored by consistent investment in machinery and equipment. Their most recent addition is a surface treatment hall, constructed last year, where they carry out blast cleaning and wet painting of finished structures.

With Nor-Maali´s industrial coatings

A substantial portion of Kuopion Rakenneasennus’s output requires surface treatment. The company has been using Nor-Maali´s industrial coatings for painting since 2011. The specific products used have varied over the years, as each project demands a unique painting system. Predominantly, the company uses epoxy or epoxy-polyurethane systems that are intended for corrosion classes C3-C5.

In addition to these “standard” products, the company also uses so-called specialty products, as Kuopion Rakenneasennus manufactures tanks that necessitate the use of chemical-resistant coatings and sea guides and beacons that require immersion-resistant coatings.

Recently, Kuopion Rakenneasennus’s product range has included epoxy primers such as Epocoat 21 HB and NorECOat FD Primer, the epoxy topcoat Norepox HS, and polyurethane coatings Normadur 65 HS and Normafine 40 HS. In addition, they have used Normastic 405 and Jotun’s Marathon 550, suitable for immersion stress, and Tankguard SF used for painting chemical tanks.

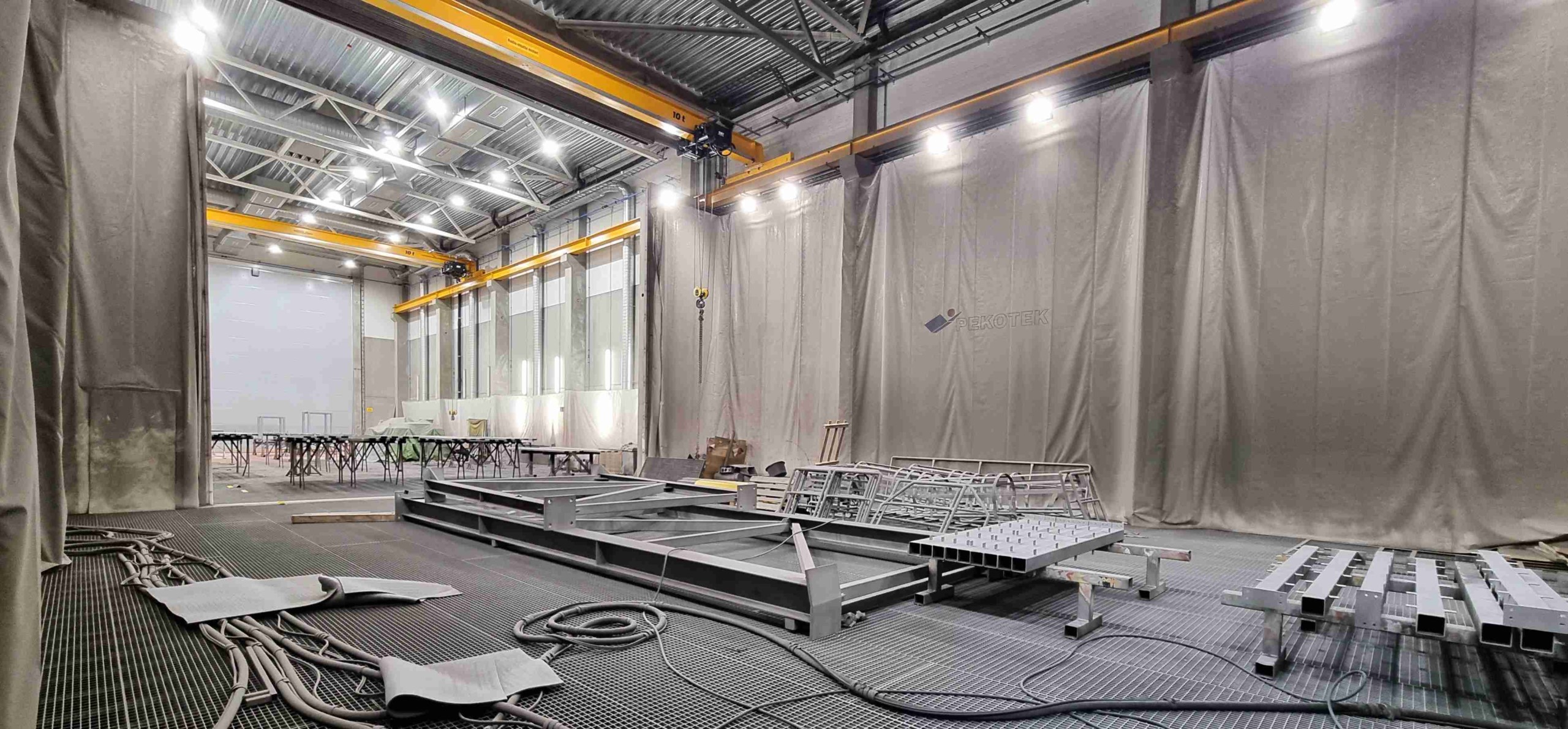

Kuopion Rakenneasennus opened the new surface treatment facility in January. The investment to this new pre-treatment area and painting shop was driven by a need for additional space and the desire to upgrade their technology. Pekotek Oy, whose equipment is now being used by the company, helped Kuopion Rakenneasennus in the design and implementation of the ventilation and blasting equipment.

The new facilities are 50 x 15 m2 in size and enable the painting of larger objects. Moreover, the installation of larger cranes has increased the operational capacity. In the new blasting system, both steel grit and alumina can be used in the same blasting chamber. The air transfer system combined with the magnetic separator guarantees excellent resolution.

In the new paint shop, conditions (temperature, air humidity, and amount of ventilation) can be controlled with precision. The residual heat from the ventilation compressors is harnessed and used to heat the production building. As such, the modernization of the surface treatment facilities has boosted the company’s energy efficiency and lowered operational costs. At present, three people are working in surface treatment.

Thanks to the new facilities and expanded capacity, Kuopion Rakenneasennus is now equipped to undertake surface treatment tasks beyond its own production, including external painting orders.

New surface treatment facility.

Kuopion Rakenneasennus paints with Nor-Maali´s coatings.

In the picture on the left, Nor-Maali's Niko Kallio and the CEO of Kuopio Rakenneasennus, Teemu Tilles.

Production facilities.