12/7/2021

Jotun Hull Skating Solutions delivers an always clean hull and help ship operators combat early-stage fouling, significantly reduce fuel costs, greenhouse gas emissions and the spread of invasive species.

The accumulation of fouling over time leads to a significant drop in performance and an increase in the vessel’s fuel consumption and environmental footprint. As the environmental and hull performance implications of fouling are better understood, innovative solutions are required to combat fouling. Jotun’s proactive cleaning solution is a ground-breaking new approach engineered to ensure optimal business and environmental performance as compared to conventional reactive cleaning methods.

There are many solutions in the market today, offering different types of anti-fouling coatings that use different types of technology to ensure that fouling will not settle on the ship’s hull. Ships using the best coating technologies suited for normal, predictable trade will not require cleaning between drydocking. However, as operations become more challenging, frequent hull cleaning will be required to maintain performance.

Aside from cleaning the antifouling during drydockings, hulls and propellers may be cleaned occasionally in water while in service. This is normally done on the so-called reactive cleaning basis, which usually takes place during the dry-docking at periods not greater than 2.5 years or when heavy fouling is evident. Today, performance monitoring software tools make it possible to detect varying degrees of fouling based upon the ship’s performance and fuel consumption data. However, at this stage fouling is already a major problem.

Traditionally cleaning would be done by teams of divers and this is still a method that is in common use. Diving teams may be good at clearing the fouling from the hull but there are problems. It is a labour intensive and costly process. Moreover, the cleaning process can lead to the coating becoming damaged and potentially creating an even worse problem in a very short time.

Much more of an issue is the effect on the environment as the cleaning process usually results in the removed matter being deposited on the seabed or left drifting in the water. This can have a detrimental effect on local ecosystems and is something that authorities are not keen on permitting. Consequently, cleaning by divers is not permitted in many ports.

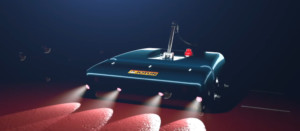

Robotic cleaning is another way to clean hulls and is being increasingly discussed in the maritime industry. The discussion on performance monitoring has led to re-thinking current coating and cleaning strategies. Also, the general progress in robotics now allows more mature technologies. However, the use of robot devices such as remote operating vehicles have traditionally been very costly and required extensive training to operate. Also, the current solutions on the market do not offer the operational flexibility of “anywhere, anytime” cleaning and inspection.

Jotun Hull Skating Solutions cleans the ships´ hulls and reduces fuel costs. Image: Jotun.

The ground-breaking new proactive cleaning approach is engineered to keep the hull free of fouling at all times as compared to conventional reactive cleaning methods.

Proactive cleaning involves cleaning the hull regularly before hard growth takes hold and prior to changing geographical bio-environment. Proactive cleaning is less aggressive causing less damage to both the coating and the local environment, whilst reducing fuel consumption on passage. The approach also reduces the risk of transporting invasive species from one bio-environment to another.

The Jotun Hull Skating Solutions is made up of five elements; high performance coatings, proactive condition monitoring, inspection and proactive cleaning, high-end technical service, clean hull guarantee; and provides a proactive, condition-based approach to in-service maintenance helping maximise hull performance in combination with Jotun’s SeaQuantum Skate coating.

Jotun’s ‘SeaQuantum Skate’ coating has been developed specifically to optimize performance in combination with the HullSkater technology. The new coating builds upon the excellent performance of the SeaQuantum brand, which is the result of over 20 years research and development in silyl acrylate technologies. SeaQuantum Skate is the only coating tailored for Hull Skating.

Jotun’s Hull Skating Solutions provides the industry with a highly professional and revolutionary inspection and proactive hull cleaning technology. A primary component is the onboard Jotun HullSkater technology.

The HullSkater is the first robotic device that has been purposed designed for proactive cleaning. It has high inspection and cleaning capacity and removes fouling without damaging the anti-fouling coating. The HullSkater is always kept onboard in a portable station with launch and recovery ramp. This means that it is always available and can be used when the ship is in harbour or at anchor, as long as there is sufficient 4G coverage for communication. The HullSkater has high capacity and the system also has high-definition inspection capabilities through multiple camera feeds, enabled by cloud-based storage, and self-supplied power. All digital data is uploaded to the cloud.

Jotun HullSkater. Image: Jotun.

The solution includes highly skilled coating advisors who ensure high performance coating application, including a comprehensive regime for measuring and documenting the quality of the application process. Also, every delivery of this solution is supported by a certified project manager, overseeing the application process and ensuring smooth instalment and set-up of the robotics. The HullSkater is remotely operated by Skate Operators working in operating hubs, enabling 24/7 support.

Proactive condition monitoring is an essential component of predictive hull maintenance. Jotun’s in-house analysts make fouling predictions based on big data trends, algorithms and analyses. When alerted by the fouling prediction algorithm, the Jotun Skate Operator contacts the ship to schedule an inspection mission and hull maintenance.

Jotun Hull Skating Solutions provide market leading hull performance through high performance coating and proactive, efficient, safe and environmentally friendly cleaning and inspections.

Image: Jotun.

https://jointherevhullution.com/

https://jointherevhullution.com/robotic-skate-can-save-aquatic-species

https://jointherevhullution.com/hull-skating-solutions

https://jointherevhullution.com/hull-skating-solutions-1

https://jointherevhullution.com/how-does-it-work

https://www.jotun.com/us/en/b2b/paintsandcoatings/ships/Hull-Skating-Solutions.aspx?q=Benefits

Nor-Maali Oy in Finland is a distributor and a licensed manufacturer for Jotun’s marine and protective coatings for Finland and Baltics States. JMC Technical Service Manager Petri Hirvensalo will be happy to help if you need more information.